Layered coating - colored plaster made with acrylic resins of grain size 1.0/1.2/1.5mm

It contains acrylic copolymers, color oxides, quartz powder, marble chips and special additives.

Layered coating - colored plaster made with acrylic resins of grain size 1.0/1.2/1.5mm

It contains acrylic copolymers, color oxides, quartz powder, marble chips and special additives.

2,5Kg – 25,0Kg

Vieroacryl RST 1.0/1.2/1.5 is a trowel-type plaster based on water-based acrylic copolymers, colored oxides, quartz powder, marble chips and special additives. The type of binder used gives the product high resistance to alkalis and atmospheric agents. The adoption of solid pigments that are very resistant to light and alkalis ensures the stability of the colors even on masonry that is particularly exposed to light radiation and bad weather conditions. This specific composition gives the product excellent characteristics of workability, elasticity and remarkable adhesion.

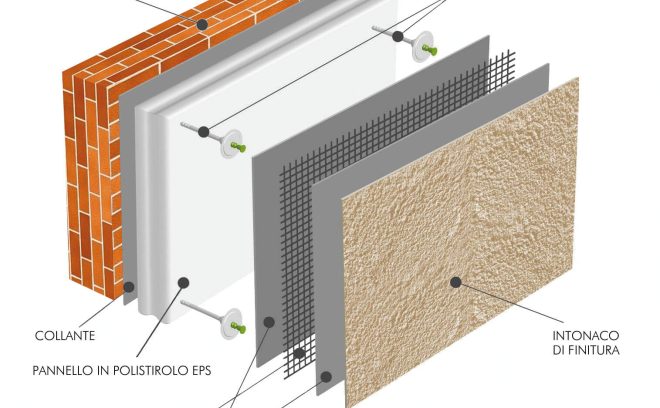

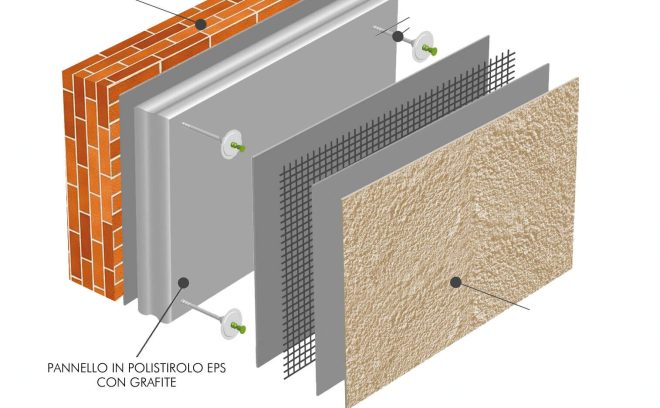

The Vieroacryl RST 1.0/1.2/1.5 colored trowel plaster based on water-based acrylic copolymers, colored oxides, quartz powder, marble chips and special additives is applied in a layer of approximately 1.0 – 1.5 mm thickness and consumption of approximately 1.8 ÷ 2.4 kg/m2. It is suitable for use on plaster, lime mortar, cement mortars, prefabricated cementitious elements and surfaces that have already been treated with other paints, properly prepared and primed with PRYMER ACQ or PRYMER PGM primer. It is part of the composite external thermal insulation systems “Vieroclima P” and “Vieroclima PV”, which enjoy the European technical approval ETA 05/0171 and ETA 11/0051

Preparation

Application

Apply a layer of Vieroacryl RST 1.0/1.2/1.5 with a stainless steel upper handle spatula. Then work the material with a plastic trowel and before it starts to dry, spread it with the same tool.

Colored acrylic-siloxane composition plaster, grain size 1.0/1.2/1.5mm, with a solid appearance

Fiber-reinforced colored plaster of siloxane composition, grain size 1.0/1.2/1.5mm, with a solid appearance

2024 Ιnterkas All Rights Reserved | Terms & Conditions